I just have not had the time to work out a bending method for the Upper Flats that I have so I have decided to put one on Gunbroker. Lets see if one of you can come up with something.

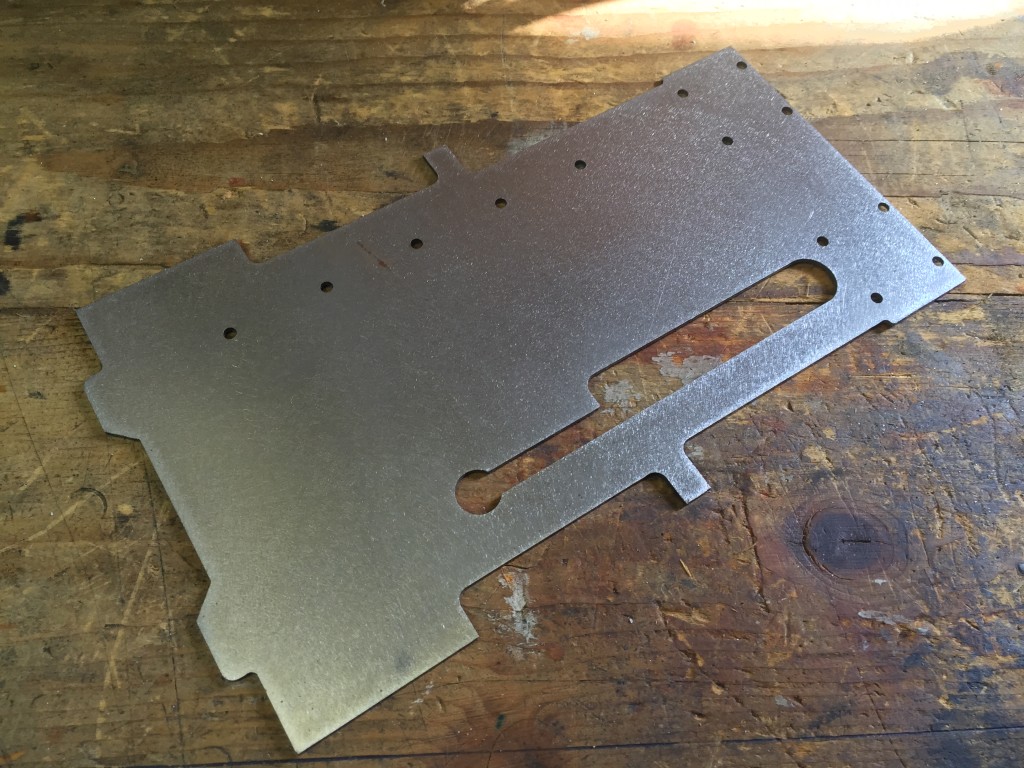

These were designed and built by Chuck at GunLab.net and match the dimensions of the factory built guns as far as I have been able to determine.

Interesting offer. What is the thickness of the Flat?

They should match as they are copied from ones I have that came from CostaMesa. They should be .063 thick 4130.

Probably would take high press pressure to get the ribs formed. The corners not so much.

Pete

Thank You for the information. .063 should be 16 gauge steel.

The jig to bend these both clean and straight is going to take a little planning. A 12 – 20 ton shop press should be able to do the work but set up and jig quality will be critical.

It would be easier if there were index holes in the area that becomes the top of the receiver. I know the rear site area could provide an indexing hole