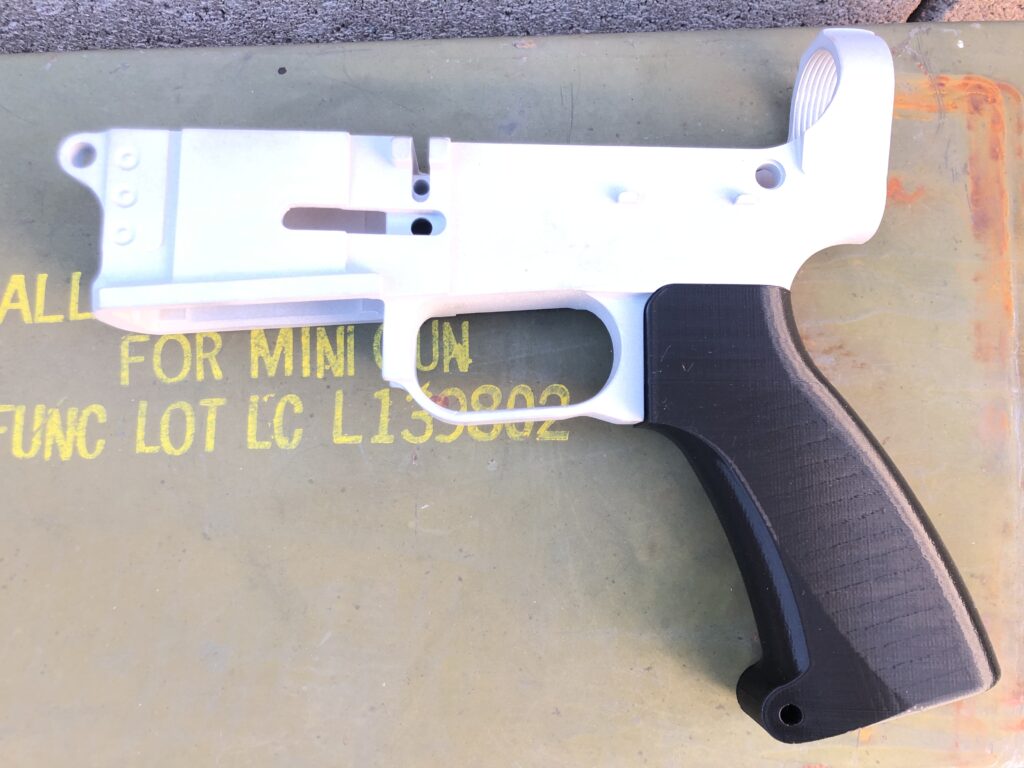

Playing with some ideas I have had floating around in my head as well as trying out some a new filament color, Army Green.

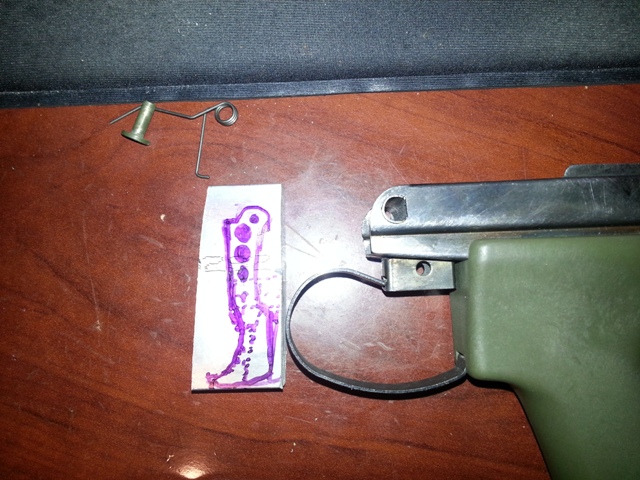

For those not familiar, the AR-16 was a prototype designed by Eugene Stoner when he still worked at ArmaLite. The furniture was wood but I always liked the shape of the hand guard. The part that stands out for me is the hand stop and the metal heat shield that sticks out the front.

I decided to give it a go and designed a couple prototypes.

So far I am very pleased with the outcome. The goal will be to creat one hand guard that works for both the long and short versions of the BRN-180. The green might not be your cup of tea but it photographs well. It will certainly be available in basic black.

What do you all think? Leave me your comments below and no this isn’t an April fools joke. I actually posted an article!