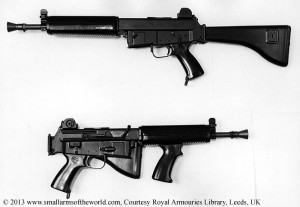

A quick update on the AR-180B Shorty Project or what I like to call it, the New AR-180S.

I had some time to attend a therapy session in my shop this past weekend and I have to say it was successful.

I have been bothered by the hand guards on this gun from the very beginning and I finally decided to do something about it.

I have tried and failed to make a retainer for the hand guards out of sheet steel like the originals. I’m good with my hands but I am no body man.

I have long thought about machining a retainer from aluminum but a figured in could only be done with CNC, which I don’t have.

I decided that I would throw caution to the wind and try to mill it manually on my mill. Whats the worst that could happen?

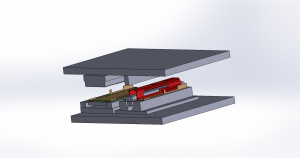

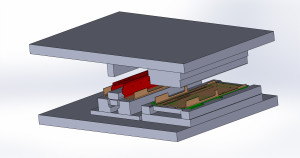

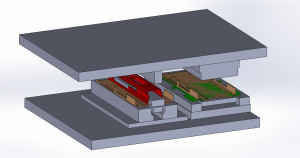

For reference, this is the method I am trying to emulate.

My original, and always temporary method, was to take the end of the cut off piece and glue it inside the remaining piece. It has already broken once and was coming loose again.

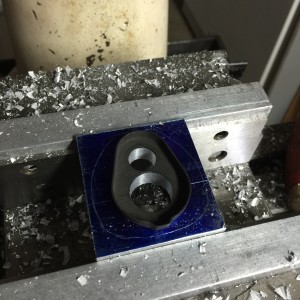

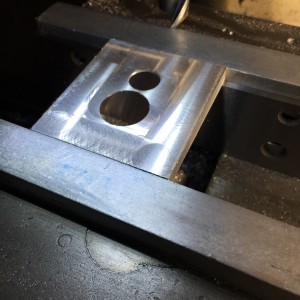

I started with a piece of 6061 and laid out the shape a needed.

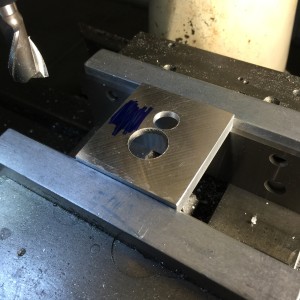

I squared up the sides then drilled out my holes and checked to see if I had my dimensions correct.

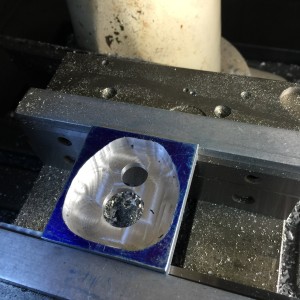

I then moved my end mill down to the depth I wanted and followed my layout lines using both knobs at the same time. This is where the therapy came in. It took a lot of concentration but in the end I think I did a pretty good job, if I don’t say so myself.

I made sure it actually fit the hand guards.

I then flipped it over and shaved it down to .035″, the same thickness as the steel retainer.

Then I trimmed up the sides on my porta-band.

And finished up with some flap disc and file work.

A final test fit.

Since I have no way to anodize I shot it with my favorite substitute, Rust-Oleum Dark Grey Primer.

And here she is an all her glory the New AR-180S!

I can’t tell you how much better the hand guards feel. They have always moved a little and never felt secure.

Now they are rock solid.

Fingers crossed that I can get some time this weekend to go shooting. I hasn’t had a round through it since it was a pistol.