Reader Eric just sent me a message via the contact page and I have to say, it is something I have never considered before. I think it is a great idea. Here is the message he sent me;

From: Eric XXXX

Subject: Can we do a poll?

Message Body:

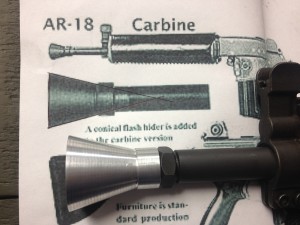

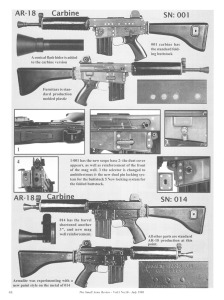

Hey guys, I was wondering if it was possible to put a poll up on the blog? Reason being, I’ve been communicating with Chuck at Gun Lab about making a bolt catch for original AR18/180’s modified to use mags with standard STANAG followers. I believe this will be a great opportunity for him plus provide us Armalite owners with a much-needed and way-overdue mod for our rifles. Simply put, no more “STANAG or Armalite” mags, just put a slit in a standard STANAG, PMAG or any of the dozens of other mags and it’ll function in the Armalite AND M16/M4/STANAG platform with a simple slit cut in the right-side mag body.

The poll would be simple…

“YES, I would buy this and maybe prepay”

“Yes, I like the idea but want to wait to see how it turns out (price, availability, quality)”

“No, I like being limited to overpriced, rare mags or modifying others to where they can’t be used in any other rifle”

Chuck might be on to one of the best mods to happen to the AR18/180 since it went to market. If we can put up a poll so he can see the interest, I’m sure he’ll move this up his “to do” list.

Thanks and thanks for the site and reviving the AR18/180 legacy!

~Eric, proud owner of a 1982 “widow-maker”

Please comment and let me know what you think of the idea.