Chuck at GunLab.net has been working on AR-180 uppers and has reverse engineered the trunion and has put up a very interesting article.

I on the other hand, lacking any semblance of expertise in CAD took a differing approach when I reverse engineered my AR-180B upper.

Good friend of the site, Carl, sent me some square tubing that he has successfully used in his home builds. I decided to duplicate my upper using this material. It is much thicker wall than the original and I will have to shave this down at least on the bottom surface to get it to work with my lowers.

I did this for two main reasons. I wanted to refresh my skills on the mill as it has been many years since I last used one, and secondly, just to see if I could.

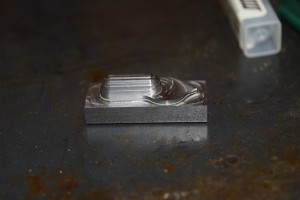

I made my first trunion out of 6061 aluminum just to test my measurements out and I have found that a few needed to be adjusted.

I learned a lot from this project and I find things like this much more rewarding than the usual beginners projects.

I will continue to tweak this until I am happy with it then I will start a new one using the first as a template. I think I will make the trunion out of 4140 unless y’all have any advice.

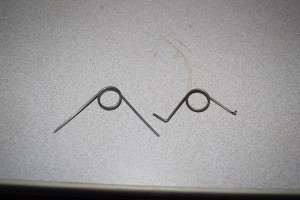

Some pictures that show what I have been up to for the last two days.

Some things to note if you attempt one of these yourself. The interior of the tubing is not perfectly square so some hand fitting will be necessary. The tubing spreads open once the bottom is cut. Some method of squeezing it back before welding would have to be considered. Lastly, all of this will be rendered moot once Chuck makes new uppers and flats available. Until then I will use this as a way to improve my machine skills and better learn my tools.