In the world of AR-180 collecting one of the top prizes could be considered the early Howa AR-180s.

Several notable features are readily apparent but some subtle clues to it’s origins are hiding just below the surface.

The most obvious feature of the rifles is the placement of the serial number, on the upper receiver as opposed to the lower.

The second is the 180 degree swing safety, which is unique to the Howa.

Some examples show a distinct misalignment of the 0 in the 180. This our first clue that these guns started life as AR-18s.

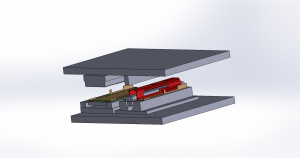

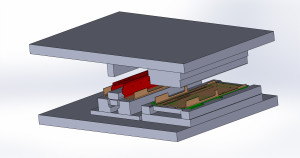

Further clues can be discovered when looking at the bottom of the upper receiver.

It is obvious when compared to the underside of an AR-18 that the part that held the auto sear has been removed.

The firing pins also look different and it looks to me like these Howas used modified AR-18 firing pins.

The really interesting thing about these guns is when they were actually made. I think the evidence makes a strong case for 1967. Much earlier than many thought.

The first piece of the puzzle is an article in the January 31. 1966 issue of U.S. News & World Report. It states that a provisional agreement was reached and Howa would undertake the first mass production of this rifle.

Japan then, during the Diet session of 1967, introduced the “Three Principles” which forbid the exportation of arms to nations in active conflict. Anyone remember what the US was doing in 1967? In southeast Asia? That’s right the Vietnam War. Howa would not have started production of a rifle they could not export so it makes sense that they were built sometime between Jan ’66 and the passing of the law in 1967.

Yet another clue, and the one first postulated by my friend and mentor, Rich, was that the earliest scopes sold in this country were originally matched up with these first 1000 Howa AR-18s. These particular AR-18s were known to have matching serial numbered flash hiders and Rich speculated that the scopes were matched as well. All the first scopes have serial numbers that start with 67 and do not go above 1000. After the rifles were banned from importation, ArmaLite ramped up production themselves and since there was no ban on the importation of the scopes, there separated from the rifles and sent to the US. These were sold as accessories with the Costa Mesa rifles.

I would like to thank all the generous folks on the retro forum at AR15.com and all those who have helped with the gathering of this information.

Like I said when I started this site, I want it to be a central depository for information about these cool guns.