My very first article as an author is coming out in Firearms News.

Look for it on newsstands November 19th or better yet subscribe!

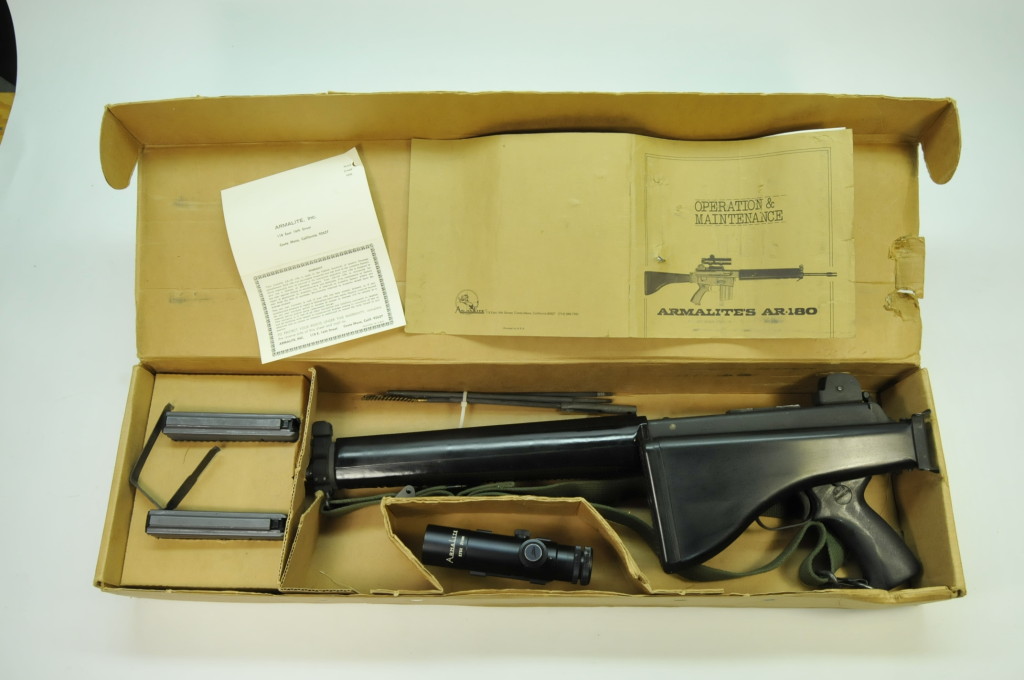

Celebrating the Armalite AR-180

My very first article as an author is coming out in Firearms News.

Look for it on newsstands November 19th or better yet subscribe!

The Fusion lowers are getting close.

These will be the 80% version that will be available through my website. When they arrive I will be testing different jigs to get an idea which ones will work. I can say with confidence that those versions that surround the entire lower and are designed for forged lower will not work without mods.

The magwell area will interfere. Those jigs that attach to the rear of the lower should work.

As well as those popular router jigs.

For those that are looking for a 100% solution I am proud to announce that Nodak Spud has licensed my design and will be producing what they call the NDS-1815. This is the first prototype and the first run should be fully machined and off to anodizing by the end of October. I’m very excited to see this come to fruition.

It’s been a long road bringing these to market but I’m sure you will be as happy with these as I am.

Well at least a few of them. According to the accepted timeline (Click Here) the first 12 AR-180 rifles were made in July 1969. 50 years ago this month.

As time marches on more and more will become Curio & Relics. Time to get your C & R FFL so we can start selling and trading these among each other. Best part, they can be mailed directly to your house!

The real question is, how do we get those who are selling them to agree they now fall under the C & R classification and it would be perfectly legal to ship them to me?

One thing is for sure, in 3 years all Costa Mesa AR-180’s will qualify for C & R status.

I welcome you comments on this. What do you think?

Good friend of the site Oscar sent me an upper that another gunsmith attempted to remove the barrel on. He got it back from said gunsmith with the message that he was unable to remove the barrel and afterwords he was unable to tighten the barrel back up.

What many do not know is that the AR180B has a unique method of barrel retention and it is not at all obvious.

If we look at a bare trunion you will note that it has a large hole through the middle with a small step.

The barrel for this gun uses an AR15 barrel extension that is turned down and press fit into this trunion. That’s it! Nothing else. Just a press fit.

What happens then when the unsuspecting gun plumber puts a barrel wrench on the barrel and clamps that flat sided receiver in his vise? It makes funny noises and turns the extension in the trunion. Not good. Oscar mentioned that it shot terrible after he got it back and I suggested he send it to me for inspection. It didn’t take long to figure out my initial thoughts were correct.

Now how do I fix it so it is safe to shoot? I want to thank Oscar for being patient with me as I have had his upper for quite some time while I try to figure out what to do.

I settled on a shallow pin. I wanted it to not show unless you were looking for it and still be able to hold everything secure.

Sneaking the Tig torch in between the bosses was challenging but ended up with good penetration after I got the amperage dialed in.

So what is the right way to remove a barrel for the 180 Bravo? Use a modified reaction wrench. Do not put any twisting force on the receiver itself.

I now have everything needed to offer shorty conversions or to sell the parts outright if you want to roll your own. CNC machined from billet steel these new hand guard caps will retain the cut down hand guards on an AR180 or 180B. Shoot me a message through the contact form if you need more details.