Project SA80 L85A2

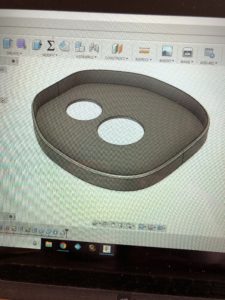

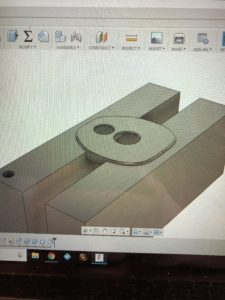

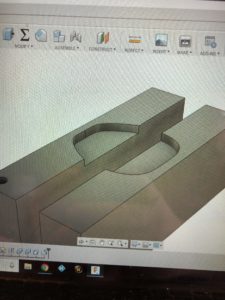

Had my daughter’s friend 3d print me some parts to mock up and it sure is easy to find your mistakes that way.

I have the firing pin retainer hole in the wrong spot as well as the charging handle. The outside dimensions are too big and the bolt carrier rubs on the inside of the upper receiver shell.

The design has been updated and I will get them printed up soon.

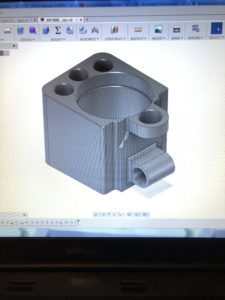

I also took the opportunity to model the original bolt carrier that I borrowed.

It is much slimmer than what I was building and it actually will ride on the airsoft guide rails since the holes are larger. This is where the frustrating part starts. When putting the original bolt and carrier in the gun it won’t strip rounds from the magazine. Either the original guide rails are lower in the receiver or the magazine is higher. I’m working on getting some more original parts to try in this shell and see where I am at.

I’m not giving up but I am having that nagging feeling that I might be stuck turning this into a .22LR instead of a 5.56.

Regardless of how it turns out I have learned a lot just from teaching myself Fusion 360 and from the study of these original parts.