This past Saturday I had the opportunity to visit Chuck at GunLab.net and it was an awesome and overwhelming experience. I wished I had taken the time to take more pictures but I think I was a little in shock at all the cool guns, parts, and equipment. By far the best part of the trip was the company, Chuck and Shirley are two of the nicest folks you could ever have the pleasure of meeting.

We chatted at length about his work on the AR-180 parts he is building. The lower parts that he is making to fit your AR-180B and Nodak NDS-18S lowers were at heat treating and should be back this week. Parkerization and final inspection along with one final operation on the springs will finish this phase. They should be ready to ship very soon.

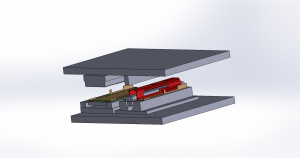

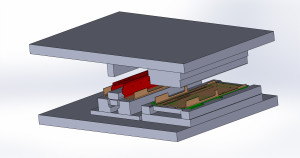

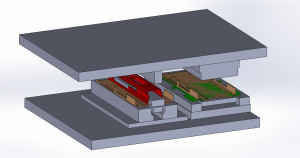

Next up he is working on uppers. We are hoping to have them available in several configurations from flats to complete uppers with trunnions and rails. He sent me some pictures of his solid model of the stamping die he is building.

Trunnions have also been modeled and those should be coming shortly after the upper sheet metal.

I also gave him one of my original prototype AR-180C railed front sight bases and I am hoping that we can get a few of those made.

The AR-180C flat top might become a reality after all!

Finally yours truly with the only picture from my visit, holding an MP-44 for the very first time. I find it astonishing that they were able to crank these out in the numbers they did, with allied bombs dropping all around them, and that the complexity of manufacture I see in this gun was actually a time saver compared to older weapons.

Make sure to subscribe so you don’t miss any new posts.