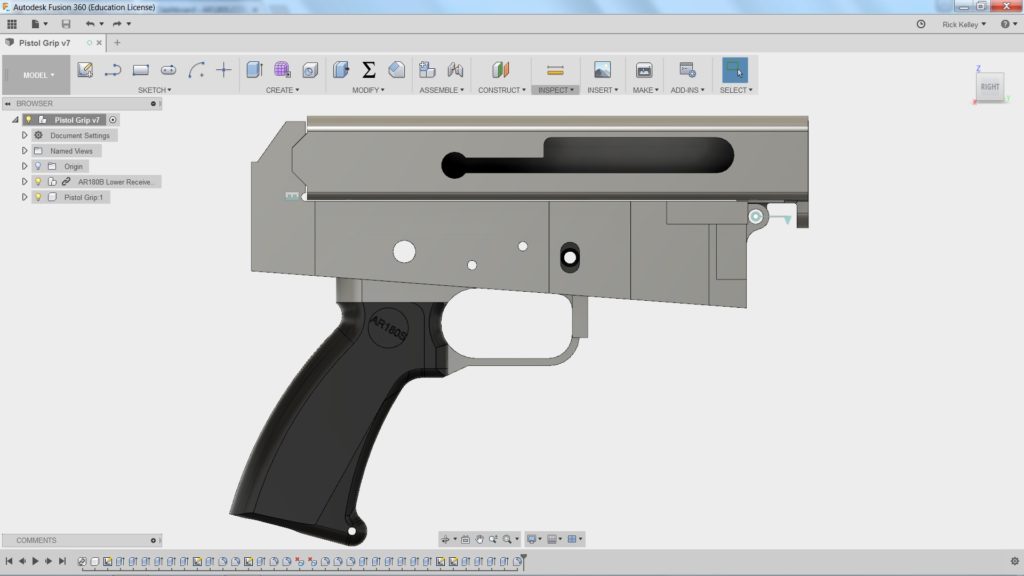

Work progresses on the AR180S Pistol Grip and I am almost happy with the result but in between test prints I do other stuff to keep my mind busy.

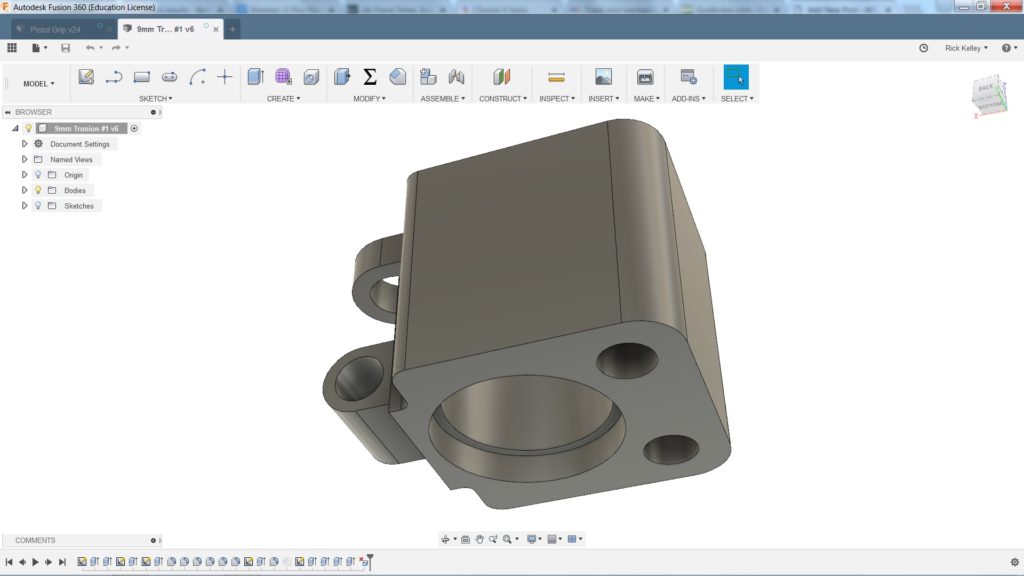

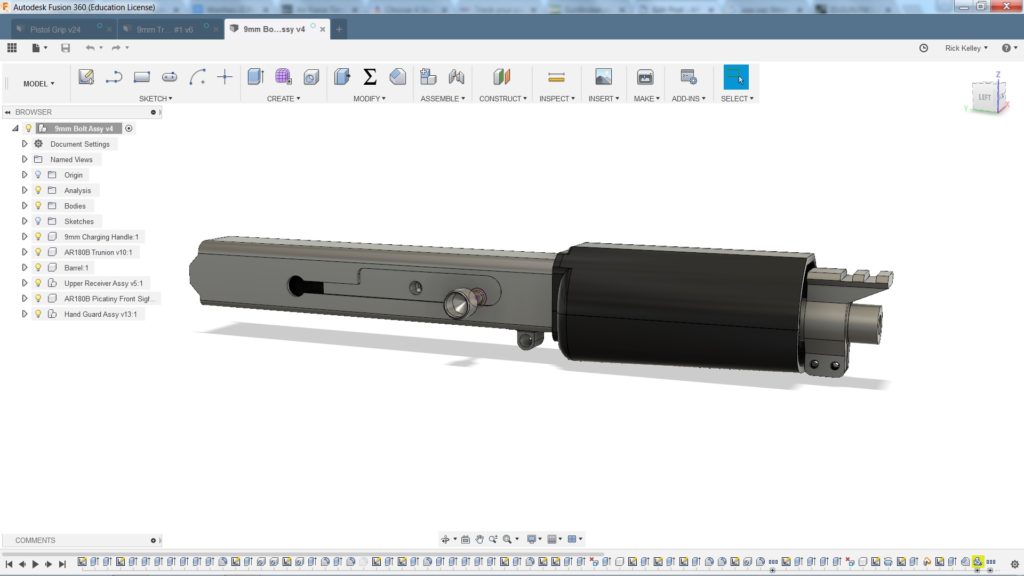

How about a 9mm blowback version of the AR180? Sounds like fun! I think this could be an easier way to build a 180 since bolts and carriers are hard to source. I think this bolt could be made with less sophisticated machines and from less expensive steel.

The pistol that got me thinking about this some years back , the 9mm Australian Automatic Arms SAP 9mm.

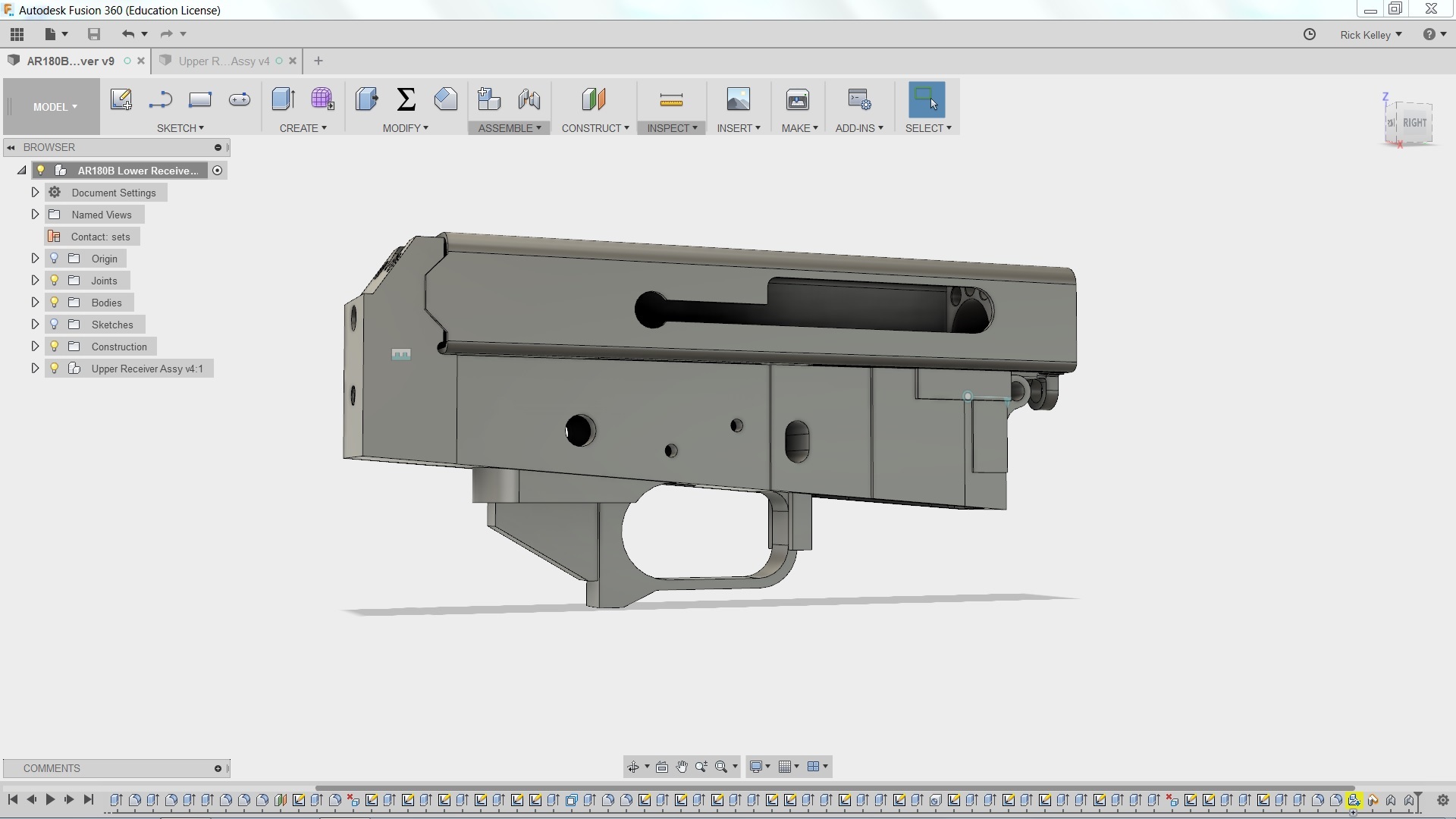

What do y’all think? AR15 magwell adapter, Slightly modified. (Shown with my long neglected square tube prototype)

3D printed prototype bolt that uses an Uzi extractor and retaining pin.

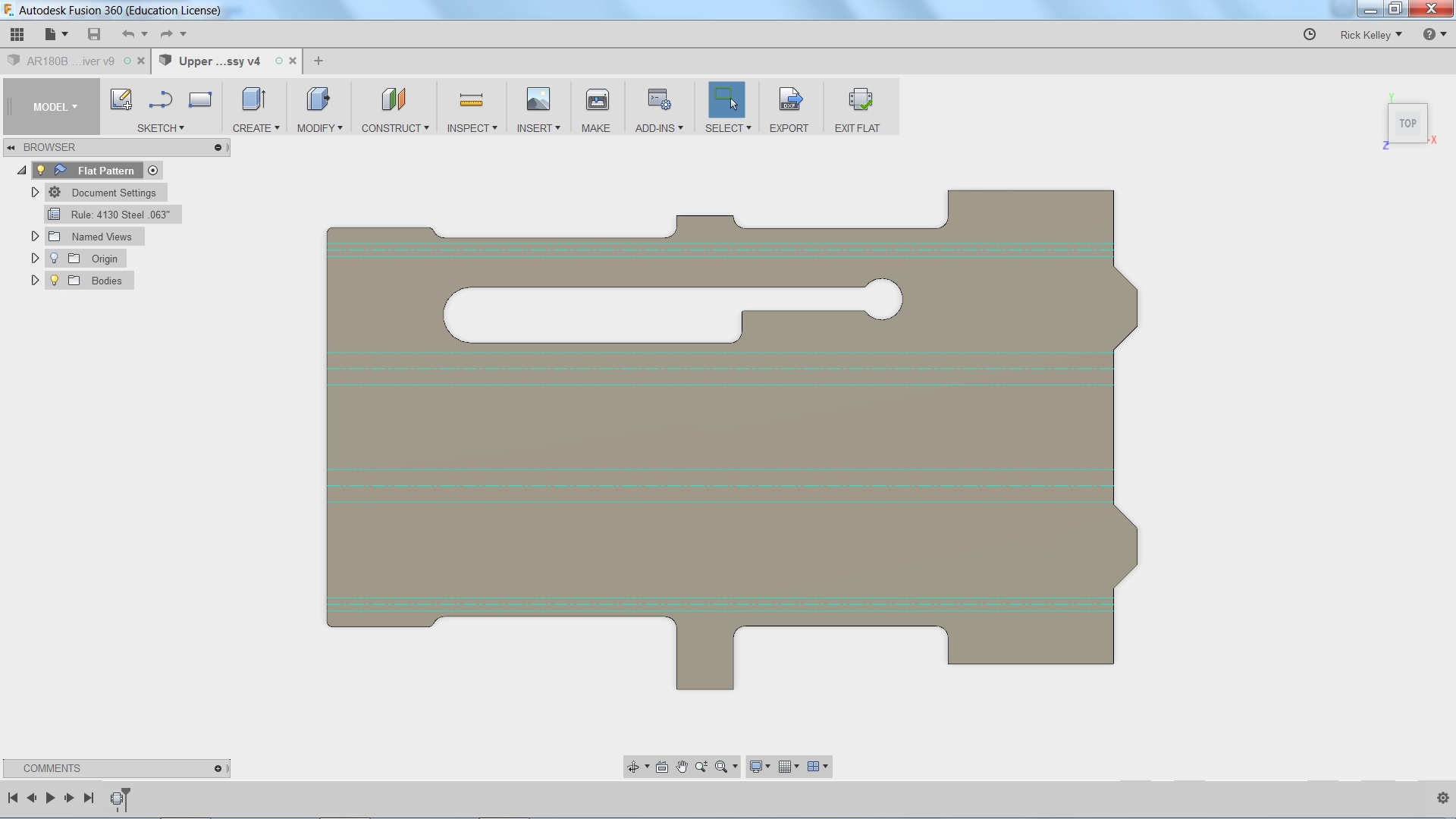

Trunion design that has the barrel entering from the rear and utilizing a press fit. Although there would be room to fit a cross pin if needed.

What I am thinking it would look like. Maybe a DOE style hang guard retainer and front sight?

Got a 9mm barrel blank from Green Mountain and a chamber reamer from MidwayUSA.

Still have some work to do on the bolt design as I discovered it would not lock the hammer onto the disconnector. I really love being able to print some stuff and test fit it before making stuff out of metal.

Project 2? Selling some stuff to finance all these projects.

I have a very limited supply of Sterling 20 round steel mags for sale. $120 each shipped with tracking. PayPal gladly excepted if you kick in a bit to cover the fees.

Other spare parts as well, just ask for my price list.

Shoot me an email through the contact form if you are interested.