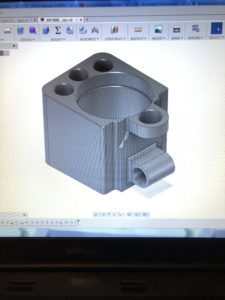

SA80 L85A2 Trunion

Still making progress on the trunion and I am hopeful I can make it work.

Progress so far.

I even got the bolt carrier to sorta feed and eject. The green one is the latest version and I made a couple tweaks and I should have it printed by the time I get back in town.

Then a present showed up in the mail.

Two reasons I wanted to see this original AR180B trunion, first to actually measure the ID of the hole so I could find out the amount of press fit. Second I want to build some. Before I can do that I need to model it right?

How did I do?

Nice! Keep up the good work, and please, an offer (group buy) might give you additional capital to bring this to fruition.

In my eyes, the trunnion and the bolt are the toughest components for a novice to even conceive of producing.

I just found this site and am just now learning of the AR180. Sounds bad but I never heard of an AR18 before. May i ask what kind of steel the Trunion is made from since you are going to weld it in too the upper part of the receiver.

Should the steel be similar to the bolt carrier. Like I said this is all new to me.

Personally why are not more of these rifles being made they seem to be a better option than an AR15.

Why are there no flats available for these rifles like the AK

I’m not sure yet what steel I will make these parts out of but I am leaning towards something like a 4130 or 4140. I don’t plan to shoot this a lot otherwise I would go for something like 8620.

Pretty neat Rick.

Early on in the 180B production I bought a few uppers that had cam pin rail issues. I asked Mark Westrom about that interference fit. I do not recall what he said but it was less than I thought it would have been. I do recall him saying it could not be too much a the area below the hole is not very thick and cracking could be a concern.

What did you come up with?

Pete

The trunion I got is egg shaped (and why it was probably not used in a production gun) so I had to split the difference and came up wit a .005″ interference fit. I can certainly see what you are referring to on the potential for cracking.